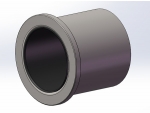

Thrust Washers

1. The #50W thrust washer made by our company is a kind of high-performance, solid-lubricated product that is mainly constructed from copper alloy. Different from common bearings, the solid-lubricated thrust washer does not depend on oil film for lubrication.

2. This product allows solid lubricant to rub against axle through frictional heat when in use. It gives outstanding lubrication performance when oil and powder coexist. The thrust washers can not only protect axle from abrasion, but also make the characteristic of solid lubricant permanent.

3. Thus far, the thrust washers have been widely used as the plastic mould accessories, packaging machine accessories, and the other transmission accessories.

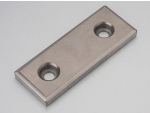

4. Please choose the part number through the appropriate inner diameter and thickness. Here is an example under conditions of 6mm inner diameter and 3mm thickness.

Technical Parameters

| Part No. | Inner Diameter | Outer Diameter | Thickness | Screw Holes | |||

| P.C.D | Number of Holes | Flat Head Screw | d1 | ||||

| 6.2 | 25 | 3 | 15 | 2 | M3 | 3.5 | |

| 8.2 | 28 | " | 18 | " | " | " | |

| 10.2 | 30 | " | 20 | " | " | " | |

| 12.2 | 40 | " | 28 | " | " | " | |

| 12.2 | 40 | " | Without flat head screw hole | 3.5 | |||

| 13.2 | 40 | " | 28 | 2 | M3 | " | |

| 14.2 | 40 | " | " | " | " | ||

| 15.2 | 50 | " | 35 | " | " | " | |

| 16.2 | 50 | " | " | " | " | ||

| 16.2 | 50 | " | Without flat head screw hole | ||||

| 18.2 | 50 | " | 35 | 2 | M3 | 3.5 | |

| 20.2 | 50 | " | " | M5 | 6 | ||

| 25.2 | 55 | 5 | 40 | " | " | " | |

| 30.2 | 60 | " | 45 | " | " | " | |

| 35.2 | 70 | " | 50 | " | " | " | |

| 40.2 | 80 | 7 | 60 | " | M6 | 7 | |

| 45.2 | 90 | " | 67.5 | " | " | " | |

| 50.3 | 100 | 8 | 75 | 4 | " | " | |

| 55.3 | 110 | " | 85 | " | " | " | |

| 60.3 | 120 | " | 90 | " | M8 | 9 | |

| 65.3 | 125 | " | 95 | " | " | " | |

| 70.3 | 130 | 10 | 100 | " | " | " | |

| 75.3 | 140 | " | 110 | " | " | " | |

| 80.3 | 150 | " | 120 | " | " | " | |

| 90.5 | 170 | " | 140 | " | M10 | 11 | |

| 100.5 | 190 | " | 160 | " | " | " | |

| 120.5 | 200 | " | 175 | " | " | " | |

Technical Parameters

Material |

#50SP1-SL1 CuZn25Al6 FeMn3 |

#50SP1-SL4 CuZn25Al6 FeMn3 |

#50SP5-SL1 CuZn25Al6 FeMn3 |

#50HP CuZn25Al6 FeMn3 |

#50AB-SL1 CuAl10Ni |

#50AB-SL4 CuAl10Ni |

#50B CuSn12 |

| Cu | 65 | 65 | 65 | 65 | 80 | 80 | 88 |

| Sn | 12 | ||||||

| Pb | 25 | 25 | 25 | 25 | |||

| Zn | 6 | 6 | 6 | 6 | |||

| Ni | 5 | 5 | |||||

| Al | 10 | 10 | |||||

| Fe | 5 | 5 | |||||

| Mn | 4 | 4 | 4 | 4 | |||

| Hardness HB |

>180 | >180 | >235 | >250 | >150 | >150 | >80 |

| Tensile strength N/mm² |

>550 | >550 | >750 | >785 | >200 | >200 | >200 |

| Elongation % |

>12 | >12 | >10 | >10 | >8 | >8 | |

| Coefficient of expansion |

1.9×10-5/℃ | 1.9×10-5/℃ | 1.9×10-5/℃ | 1.6×10-5/℃ | 1.8×10-5/℃ | 1.8×10-5/℃ | |

| Limited Temp ℃ |

300~400 | 300~400 | 300~400 | 400 | 400 | 400 | |

| Max load N/mm² |

80 | 100 | 118 | 50 | 70 | 70 | |

| MAX SPEED M/min |

15 | 15 | 10 | 20 | 10 | 10 | |

| Max PV N/mm2*m/s |

200 | 200 | 200 | 200 | 200 | 200 | |

| Compression set amount 400 N/mm² |

<0.01 | <0.01 | <0.05 | <0.04 | <0.05 | <0.05 |

Chinese

Chinese English

English Português

Português Русский

Русский Español

Español Deutsch

Deutsch