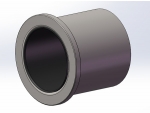

Home » Products » Metal Bearings» Self-Lubricating Bearings » #50S Self-lubricating Spherical Bearing

#50S

Self-lubricating Spherical Bearing

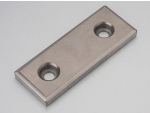

1. The #50S self-lubricating spherical bearing is universally applicable to the hydraulic ram, irrigation machinery, and the other heavy-duty machines. Unique structure allows the hydraulic ram bearing to withstand the radial load, thrust load, or a combined load.

2. Our globe bearing generally has a copper exterior and a stainless steel interior. It can be designed with different materials in accordance with the requirements of our customers.

3. Please choose the part number via suitable inner diameter. Here is an example when inner diameter of the self-lubricating spherical bearing reaches 15mm.

Technical Data

| Part No. | Dimensions mm |

Alignment Angle α° | Allowable Radial Load (kN) | Allowable Thrust Load (kN) | ||||||

| Model | d | H7 | D | h6 | B | C | dk | |||

| 15 | +0.0180 | 26 | 0-0.013 | 12 | 9 | 22 | 8 | 6.5 | 0.5 | |

| 20 | +0.0210 | 32 | 0-0.016 | 16 | 14 | 28 | 4 | 12.6 | 1.4 | |

| 25 | " | 42 | " | 21 | 18 | 36 | 5 | 21.8 | 2.5 | |

| 30 | " | 50 | " | 27 | 23 | 44 | 6 | 32.0 | 3.5 | |

| 35 | +0.0250 | 55 | 0-0.019 | 30 | 26 | 49 | 5 | 437.0 | 4.8 | |

| 40 | " | 62 | " | 33 | 28 | 55 | 6 | 54.7 | 5.7 | |

| 45 | " | 72 | " | 36 | 31 | 62 | 5 | 69.7 | 7.2 | |

| 50 | " | 80 | " | 42 | 36 | 70 | " | 92.4 | 10 | |

| 60 | +0.0350 | 100 | 0-0.025 | 53 | 45 | 90 | 6 | 143 | 16 | |

| 70 | " | 110 | " | 58 | 50 | 99 | 5 | 181 | 20 | |

| 80 | " | 130 | " | 70 | 60 | 115 | 6 | 254 | 30 | |

| 90 | +0.0180 | 140 | " | 76 | 65 | 125 | " | 313 | 36 | |

| 100 | " | 160 | " | 88 | 75 | 145 | " | 544 | 64 | |

| 110 | " | 170 | " | 93 | 80 | 155 | 5 | 642 | 73 | |

| 120 | " | 190 | " | 105 | 90 | 170 | 6 | 797 | 94 | |

| 130 | +0.0400 | 200 | " | 110 | 95 | 180 | 5 | 880 | 105 | |

| 140 | " | 210 | " | 90 | 70 | 180 | 7 | 668 | 56 | |

| 150 | " | 220 | " | 120 | 105 | 200 | 5 | 1135 | 129 | |

| 160 | " | 230 | " | 105 | 80 | 200 | 8 | 891 | 73 | |

| 180 | " | 260 | 0-0.032 | 105 | 80 | 225 | 6 | 1002 | 74 | |

| 200 | +0.0460 | 290 | " | 130 | 100 | 250 | 7 | 1434 | 117 | |

| 220 | " | 320 | 0-0.036 | 135 | 100 | 275 | 8 | 1577 | 118 | |

| 240 | " | 340 | " | 140 | 100 | 300 | " | 1720 | 118 | |

| 260 | +0.0520 | 370 | " | 150 | 110 | 325 | 7 | 2072 | 143 | |

| 280 | " | 400 | " | 155 | 120 | 350 | 6 | 2455 | 172 | |

| 300 | " | 430 | 0-0.040 | 165 | 120 | 375 | 7 | 2630 | 172 | |

Technical Parameters

Material |

#50SP1-SL1 CuZn25Al6 FeMn3 |

#50SP1-SL4 CuZn25Al6 FeMn3 |

#50SP5-SL1 CuZn25Al6 FeMn3 |

#50HP CuZn25Al6 FeMn3 |

#50AB-SL1 CuAl10Ni |

#50AB-SL4 CuAl10Ni |

#50B CuSn12 |

| Cu | 65 | 65 | 65 | 65 | 80 | 80 | 88 |

| Sn | 12 | ||||||

| Pb | 25 | 25 | 25 | 25 | |||

| Zn | 6 | 6 | 6 | 6 | |||

| Ni | 5 | 5 | |||||

| Al | 10 | 10 | |||||

| Fe | 5 | 5 | |||||

| Mn | 4 | 4 | 4 | 4 | |||

| Hardness HB |

>180 | >180 | >235 | >250 | >150 | >150 | >80 |

| Tensile strength N/mm² |

>550 | >550 | >750 | >785 | >200 | >200 | >200 |

| Elongation % |

>12 | >12 | >10 | >10 | >8 | >8 | |

| Coefficient of expansion |

1.9×10-5/℃ | 1.9×10-5/℃ | 1.9×10-5/℃ | 1.6×10-5/℃ | 1.8×10-5/℃ | 1.8×10-5/℃ | |

| Limited Temp ℃ |

300~400 | 300~400 | 300~400 | 400 | 400 | 400 | |

| Max load N/mm² |

80 | 100 | 118 | 50 | 70 | 70 | |

| MAX SPEED M/min |

15 | 15 | 10 | 20 | 10 | 10 | |

| Max PV N/mm2*m/s |

200 | 200 | 200 | 200 | 200 | 200 | |

| Compression set amount 400 N/mm² |

<0.01 | <0.01 | <0.05 | <0.04 | <0.05 | <0.05 |

Chinese

Chinese English

English Português

Português Русский

Русский Español

Español Deutsch

Deutsch