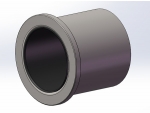

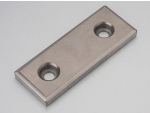

Self lubricating Bearing

The DNB#200-T Self lubricating Bearing is composed of wear-resistant sintered layer and metal substrate.

Sintered Layer

The sintered layer is produced from special copper alloy, equally distributed graphite, and PTFE solid lubricant, to generate solid lubricating film with low coefficient of friction and low shearing strength during micro-movement of the composite bearing. Even under heavy load, the mating surface can be covered with the lubricating film, perfectly.

Metal Substrate

The metal substrate of the Self lubricating Bearing is meticulously designed for outstanding mechanical strength and dimensional stability. Generally, Q235 carbon steel is used for exceptional load carrying capacity, offering working function equivalent to DEVA BM bearings. Based on actual customer demand, we can also manufacture the metal bearing with stainless steel or copper substrate. In addition, surface coating is optional for good resistance to corrosion.

Features

1. The Self lubricating Bearing is produced with advanced metallurgical technology.

2. It provides lubricating film for the bushing.

3. The oil-free copper bearing has good high temperature resistance, wear resistance, and corrosion resistance.

4. Our product will not be contaminated easily and is capable of affording big pressure at bearing edge.

5. The wear resistant bearing can be machined easily to satisfy diversified customer demands.

6. With good resistance to abrasion and the temperature from -40°C to 400°C, the machine element can function normally for 5,000 hours without troublesome oil lubrication.

7. High pressure bearing capacity. The maximum pressure can be 118P (N/mm²).

8. The warranty period of the Self lubricating Bearing is 3 years. Within warranty period, we will offer the replacement in case the wear-resistant layer of the product is worn out.

The Self lubricating Bearing is widely applied in different industries, such as injection molding machine, printing machine, construction equipment, among others. It is particularly suitable for the device that is started frequently to generate reciprocating, rotational and oscillating movement.

Technical Parameters| Model | Material | Solid lubricant | Hardness | Deformation (150MPa) | Static load | Dynamic load | Max. line speed | Max. PV | Coefficient of friction | Working temperature (°C) |

| DNB#200-T | CuSn12+graphite+PTFE | 8-10% | >40HB | No | 180N/mm2 | 120N/mm2 | 0.5m/s | 1.5N/mm2*m/s | <0.3 | -40 to 400 |

Dernore started the research and development of the metal bearing in 2008. Up to now, we have set up cooperative relationship with domestic segmented tire mould and container manufacturer, successfully.

Chinese

Chinese English

English Português

Português Русский

Русский Español

Español Deutsch

Deutsch