Solid Lubricated Guide Rail

1. The #50L solid lubricated guide rail combines the wear-resisting property of copper alloy with the self-lubricating property of solid lubricant. In this way, it can be used without oiling and maintenance.

2. The copper alloy guide track is widely applied in high-load, intermittent or oscillating motion, e.g., the auto stamping moulds, injection moulds, and the general machinery, etc. Various types of copper alloy can be provided in accordance with working conditions.

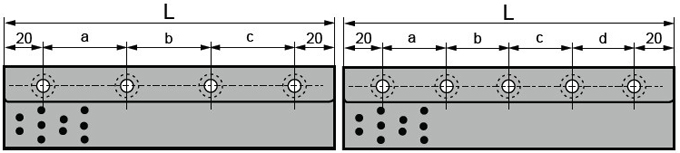

3. Please choose the part number of the general machinery guide way in compliance with suitable width and length.

4. For instance, the ordering code of the solid lubricated guide rail is DNB-#50L-20100 under conditions of 20mm width and 100mm length.

Main Specifications

| Part No. | Width | Length | Bolt Hole | Sketch | |||||

| a | b | c | d | Size | Qty. | ||||

| 20 | 100 | 60 | - | - | - | M8 | 2 | A | |

| 20 | 150 | 55 | 55 | - | - | " | 3 | " | |

| 20 | 200 | 55 | 50 | 55 | - | " | 4 | " | |

| 30 | 100 | 60 | - | - | - | M10 | 2 | B | |

| 30 | 150 | 55 | 55 | - | - | " | 3 | " | |

| 30 | 200 | 50 | 50 | 55 | - | " | 4 | " | |

| 30 | 250 | 70 | 70 | 70 | - | " | 4 | " | |

| 45 | 200 | 55 | 50 | 55 | - | " | 4 | C | |

| 45 | 250 | 70 | 70 | 70 | - | " | 4 | " | |

| 45 | 300 | 65 | 65 | 65 | 65 | " | 5 | " | |

| 45 | 350 | 80 | 75 | 75 | 80 | " | 5 | " | |

Technical Parameters

Material |

#50SP1-SL1 CuZn25Al6 FeMn3 |

#50SP1-SL4 CuZn25Al6 FeMn3 |

#50SP5-SL1 CuZn25Al6 FeMn3 |

#50HP CuZn25Al6 FeMn3 |

#50AB-SL1 CuAl10Ni |

#50AB-SL4 CuAl10Ni |

#50B CuSn12 |

| Cu | 65 | 65 | 65 | 65 | 80 | 80 | 88 |

| Sn | 12 | ||||||

| Pb | 25 | 25 | 25 | 25 | |||

| Zn | 6 | 6 | 6 | 6 | |||

| Ni | 5 | 5 | |||||

| Al | 10 | 10 | |||||

| Fe | 5 | 5 | |||||

| Mn | 4 | 4 | 4 | 4 | |||

| Hardness HB |

>180 | >180 | >235 | >250 | >150 | >150 | >80 |

| Tensile strength N/mm² |

>550 | >550 | >750 | >785 | >200 | >200 | >200 |

| Elongation % |

>12 | >12 | >10 | >10 | >8 | >8 | |

| Coefficient of expansion |

1.9×10-5/℃ | 1.9×10-5/℃ | 1.9×10-5/℃ | 1.6×10-5/℃ | 1.8×10-5/℃ | 1.8×10-5/℃ | |

| Limited Temp ℃ |

300~400 | 300~400 | 300~400 | 400 | 400 | 400 | |

| Max load N/mm² |

80 | 100 | 118 | 50 | 70 | 70 | |

| MAX SPEED M/min |

15 | 15 | 10 | 20 | 10 | 10 | |

| Max PV N/mm2*m/s |

200 | 200 | 200 | 200 | 200 | 200 | |

| Compression set amount 400 N/mm² |

<0.01 | <0.01 | <0.05 | <0.04 | <0.05 | <0.05 |

Chinese

Chinese English

English Português

Português Русский

Русский Español

Español Deutsch

Deutsch